Advantages of Metal Stamping Parts

1.High Production Efficiency

Ideal for large-volume production with consistent quality,fast cycle times reduce lead time and labor cost

2.Excellent Dimensional Accuracy

Tight tolerances achievable through progressive dies and precision tooling ,stable part repeatability, even for complex geometries

3.Lower Material Waste

Optimized nesting and die design maximize raw material utilization,cost-effective for both ferrous and non-ferrous metals

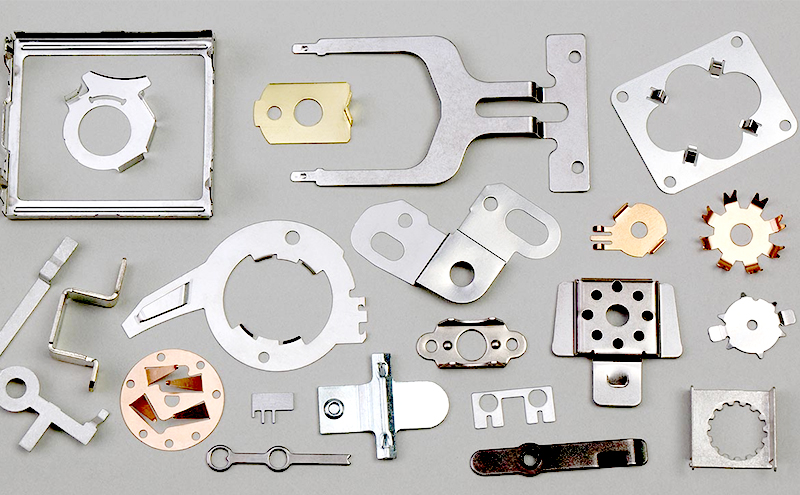

4.Versatile Design Capabilities

Supports deep drawing, bending, punching, embossing, and coining,complex parts can be formed in a single or progressive stamping stage

5.Enhanced Structural Strength

Cold-forming increases material strength without heat treatment,durable for load-bearing and high-wear applications

6.Cost-Effective for Mass Production

Once tooling is ready, unit cost drops significantly for large orders,ideal for automotive parts, brackets, enclosures, and fasteners